A Very Merry Case Study: Optimal automation tackled the demanding peak season and saved Christmas

Busy seasons are tricky in any warehouse. No matter how prepared you are, handling the workload when the peak comes may be challenging. This was the situation at S.C. Manufacturing and Warehousing site in North Finland. With a carefully selected and purpose-built logistic solution, the site could streamline the process and make it more controlled to ensure operational reliability.

CAUTION: You are hereby notified that what you are about to read is highly confidential and shared under the permission of S.C. Manufacturing and Warehousing. All processes were performed by professionals. No reindeer or elves were harmed during the making of this project.

Holiday season in danger

S.C. Manufacturing and Warehousing (S.C. M&W) has an exceptionally vast factory site in Korvatunturi, North of Finland, comprehending a production site, a warehousing site and an international shipment hub. The operation is highly seasonal, peaking in December, and the warehouse personnel have challenges tackling the workload. The functions are critical, and operation interruptions can drastically affect the success of the holiday season around the world.

“Our workers at the Toy Factory and the Warehouse are our most valuable asset. Thus, we want to offer good working conditions where the workers can thrive. When exhausted, the number of errors grows high, and the damage is created not only to goods but for the workers as well, which is unacceptable!” explains E.L. Flake, Warehouse Manager at S.C. M&W.

S.C. M&W was searching for a long-term partnership with a solution provider who could build a comprehensive solution covering the whole logistics, including the inbound and outbound areas and warehousing. Solving the traffic peaks, streamlining the handling of goods, minimising wastage, ensuring operational reliability and taking care of the employees’ well-being were the primary targets that needed to be tackled with a customised logistics solution.

Dashing through the warehouse aisles

The project started by carefully analysing our customer’s site. The Logisnext Solutions team visited the facility to study the operations, processes (the data system, interface, and the forecast of the material flow), and picking performance. They calculated the number of movements between the locations, examined the load specifications (in this case, very varied), and studied the rack and floor specifications. Warehouse Manager E.L. Flake was there to help our team with the specifications alongside the process.

“The schedule was tight, and the number of operations was very high, but as our customer is a critical global actor, we wanted to ensure our proposal would cover all the pain points. We always listen to our customers and want to have a thorough understanding of the core of their business, their current situation and the issues. Together, we determine the goals of the project and the KPIs,” says Petri Petäys, Sales Director at Mitsubishi Logisnext Europe Oy (MLE Oy).

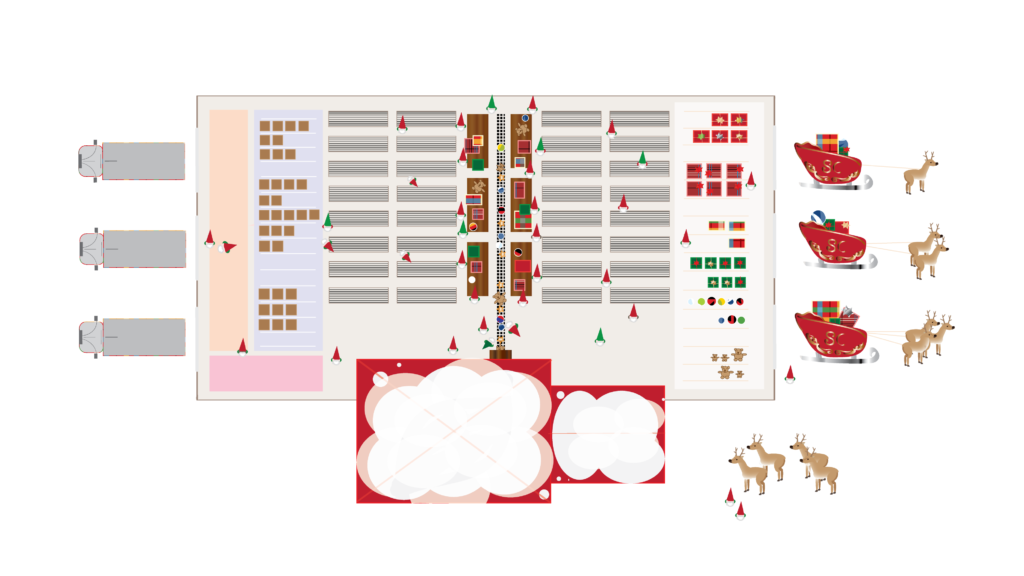

S.C. M&W consists of a one-level, heated warehouse that employs over 20,000 workers. The layout of the facility embodies the reception, the inbound, the storage of the materials, the assembly line, the storage of the finished goods and the outbound area. The warehouse receives all sorts of materials: boxes and pieces for toys and gifts. The toy factory is also connected to the warehouse and brings toys and wrapping paper directly to the assembly area, where the elves personalise the gifts and get them ready to be shipped.

S.C. Manufacturing and Warehousing site:

- Area: 10–50 000 m²

- Pallet locations: 15–70 000

- Lift heights: 5–11 m

- Fleet size: 100–500 forklifts

- Storage type: Reach mast aisles

- Storage units: EUR and CHEP pallets

Mixed Fleet approach: AGVs, manually operated equipment and reindeer in synergy

After thoroughly analysing the needs, seeing the facilities and hearing more about the process and wishes of the customer, the Logisnext Solutions team started to develop a comprehensive solution. As the demand at the customer’s warehouse is seasonal and there are exceptions from time to time, finding the optimal level of automation was the key; thus, only some parts of the process were meant to be automated. The AGVs can handle most of the picking and spare the workers from dangerous and wearisome tasks. But during peak hours, the workers could help using manually operated forklifts. This way, the number of AGVs is optimal, resulting in an economically viable solution.

The Mixed Fleet approach, the perfect balance between automation and manual operations, was the most suitable solution for this customer’s needs. It ensures maximum capacity use of fleets and the ability to adjust to variations in capacity demands. The FleetController was an essential part of the solution to run operations smoothly. It offers one platform that connects all components needed to run and manage efficient operations. It integrates with the warehouse management system and manages the transports. A set of optimisation algorithms ensures the fleet’s maximum capacity. Through continuous optimisation, the orders and routes are computed for fluent, efficient traffic flow at all times.

Project realisation by Logisnext Solutions:

- 10 manually operated forklifts

- 15 Rocla AGVs with a high lifting capability of 10 meters

- Improved warehouse capacity: 50–200 pallets per hour

- Safety tags for reindeer and elves to ensure the fluent operation

- Efficient racking layout

- Full Service package with complete life cycle care

- ROI: 12 months of payback time

Have yourself a perfectly fitted solution

When the solution was finalised and approved by S. Claus, CEO of S.C. M&W, it was time to start the installation and all the work on site. We equipped the warehouse with AGV guiding reflectors, charging points and all the IT needed for the solution. When everything was in place, all the functions were carefully tested. At this point, the customer was also trained to use the solution.

“Automation solution minimised the damage often caused by elf errors and other circumstances, as our employees tend to get playful when tired. Now, their skills and expertise can be used for tasks where the elf touch is critical such as, in this case, processing and personalising the goods. The Mixed Fleet solution serves us well, and I was happy to discover that the solution was easy to implement. Also, the training received good employee feedback,” tells Warehouse Manager E.L. Flake.

“We help our customers make the processes efficient. The mission is to bring the best practices to action at their warehouse. As a project, this was intense and exceptional, but we did pull it off. All this was done in-house by Logisnext Solutions.” says Teppo Rinta-Filppula, Project Director at MLE Oy.

It’s beginning to look a lot like we saved Christmas

After the final acceptance, it was time to hand over the project. Of course, the customer will never be left alone: at Logisnext Solutions, we support our customers throughout the process. We have maintenance operations and support services available both locally and globally 24/7. With such delicate operations as S.C. M&W has, the Full Service was an obvious choice as it ensures the customer doesn’t need to worry about the fluency of operations. The Full Service package covers planned and software maintenance, repairs of unexpected failures and spare parts.

“We have very high standards for safety and sustainability, and we were glad to see our strategy was met well by the MLE team. The employees can work more safely and in a less burdensome environment. Equally, the damage is minimised when the AGVs move the heavy pallets and goods. This means happier employees, safer work conditions and minimised wastage.” says Mr Claus and continues:

“Also, having a trusted partner to carry out the project was essential for us. We can trust that everything works and get expert help as quickly as possible if something happens. This is why we selected Logisnext. In a business like this, you can’t risk it! Ho, ho, ho.”

DISCLAIMER: Even though this case study, all names and figures are fictitious, and no identification with actual people, places and companies is intended and should not be inferred, the solutions, features and our experts are very much real and available to implement a similar solution for your case.

Contact us to hear more about Rocla AGV Solutions and the Mixed Fleet approach, and remember to have a look at how everything started.

#VeryMerryRoclaCaseStudy