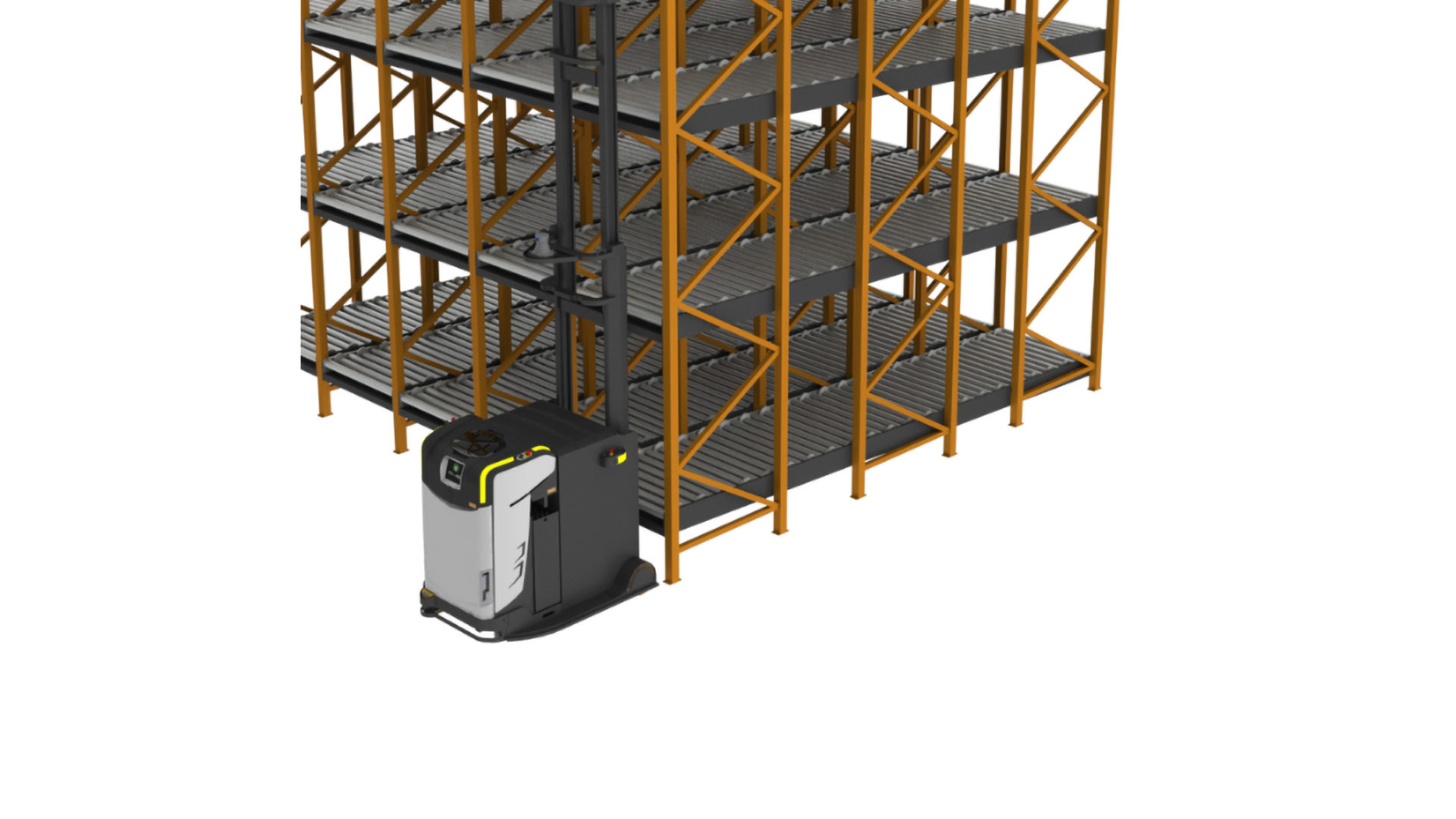

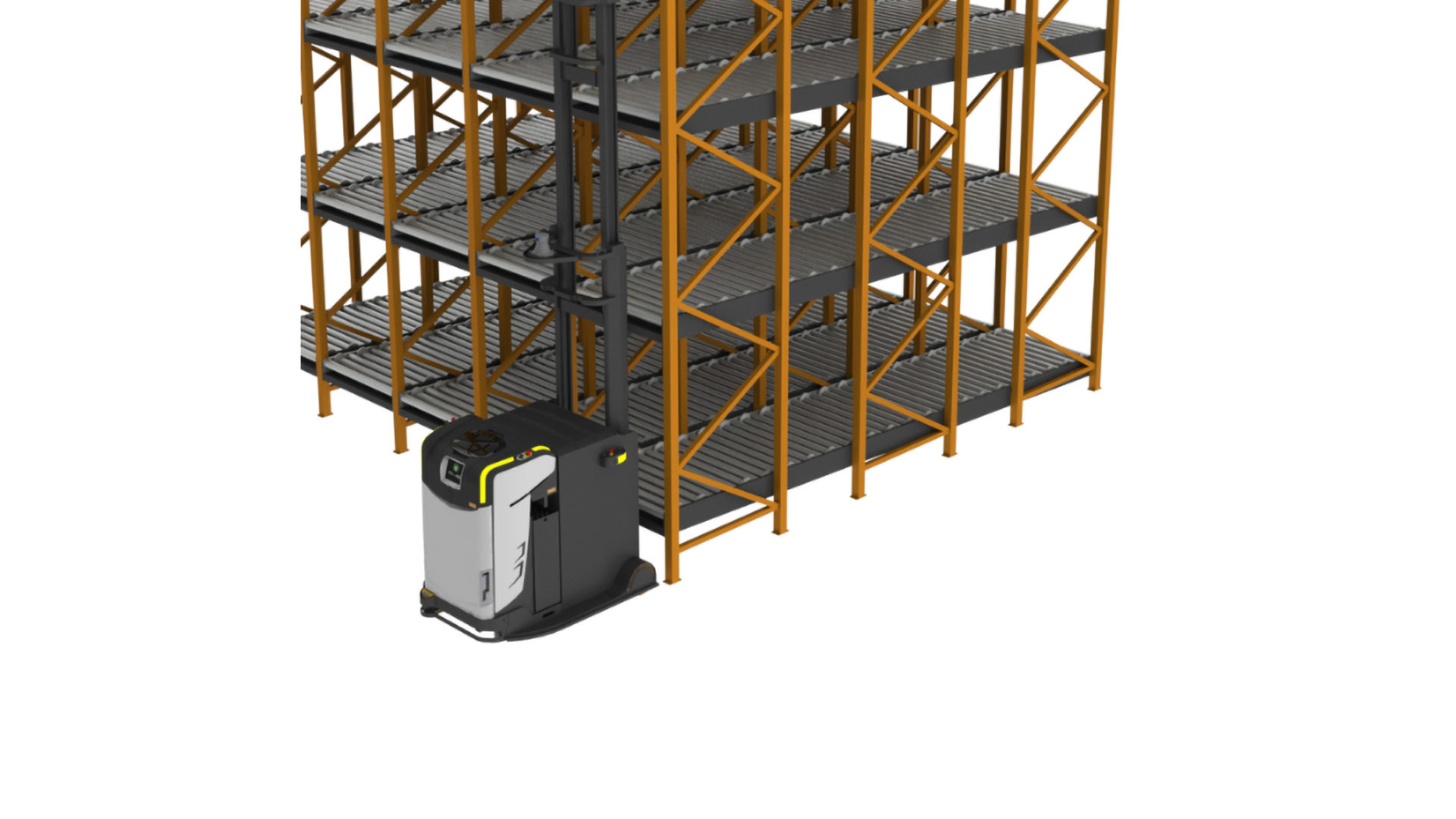

Pallet Gravity Flow Racking

Pallet gravity flow racking offers compact storage for high-frequency goods in settings with a number of different articles.

Pallet gravity flow racking offers compact storage for high-frequency goods in settings with a number of different articles.

Gravity flow racking is used in many places in manufacturing industry and it suits well, for example, as work-in-progress storage. It enables the first in, first out (FIFO) principle.

In this method, the racking is sloped and equipped with rollers. The goods move forward from intake to retrieval thanks to the force of gravity. The goods can roll on undriven conveyors with braking rollers, driven rollers, or wheeled load carriers.

Would you like to start saving costs at your warehouse or logistics facility? Please send us a message and we will get back to you.

"*" indicates required fields