Automated Compact Truck ACT

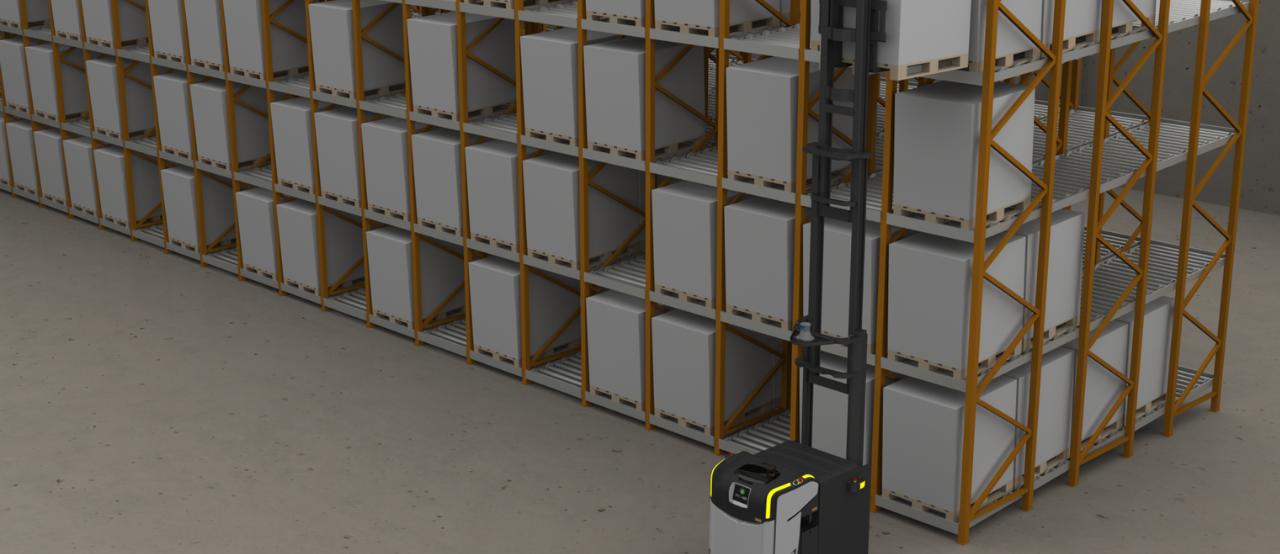

The automated compact truck (ACT) is ideal for heavy-duty lifting in narrow spaces. With a strong hydraulic unit, ACT can lift heavy loads up to 6 m in as narrow as 2.6 m aisles. Thus, it is an excellent choice for higher warehouses, where it works as a companion for other high-lifting vehicles and manually operated forklifts. ACT operates easily between warehouse and production or inbound and outbound areas, and it fits easily in the existing warehouse environment with minimal rack modifications.

ACT is the winner of iF Design Award 2024 and Red Dot Design Award 2024.

”

Key Benefits of Automated Compact Truck ACT

- Available as forkover and counterbalance

- Enables heavy lifting to 6 m even as narrow as 2.6 m aisles

- Easy integration; fits in existing warehouse logistics

- Responsive user interface

- Designed to meet ISO 3691-4 safety standard

- Designed to operate in the same environment with manual operations

The Automated Compact Truck ACT is optimal for these applications

ACT is developed with optimal automation in mind. This means harmonious interaction between AGVs and manual operations, where all actors seamlessly communicate with each other and share the tasks. ACT works incredibly effectively with other warehouse AGVs, such as ART and VNA machines, completing our comprehensive range for warehouse needs. ACT has several features to make the cooperation smooth. The touchscreen on the vehicle is highly responsive; it has fast haptics and excellent visibility from different angles. With instructive colour-coded information, the conveying information is quick and clear. LED fins on both sides of the vehicle act as turn signals and show the state of ACT from a distance for better communication with warehouse personnel.

ACT meets the ISO 3691-4 safety standard requirement. It has comprehensive safety features like 360° safety fields and side clearance monitoring. By signalling its status with lights and sound, ACT makes the warehouse work safer and more efficient. Proximity detection allows AGVs, forklifts and people with tags to detect each other without a direct line of sight, slowing the vehicle down and stopping if necessary.

Optimised amounts of automation help our customers get the maximum capacity of fleets and remain agile and flexible. Contact our specialists to learn more.

Automated Compact Truck ACT

The ACT is suitable for these industries

In the solution, the AGV is just the beginning of the story

ACT Brochure

Maximising your logistic performance

Rocla ACT Automated Compact Truck is the ideal solution for heavy-duty lifting in narrow spaces and operating efficiently between the warehouse and production or inbound and outbound areas.

ACTcf Dimensional Drawing

Download this document to learn more about the dimensional and space requirements of the ACTcf.

*Dimensions are indicative only. Details are subject to change.

ACTff Dimensional Drawing

Download this document to learn more about the dimensional and space requirements of the ACTff.

*Dimensions are indicative only. Details are subject to change.