Eyes in the future: warehouse optimised to perfection

Last year, we celebrated our 40th year in the automation business. Since 1983, thousands of Rocla AGVs have contributed to customers’ success by labouring reliably and efficiently in their warehouses within several industries. The solid experience enables us to have ambitious plans for the future with even more comprehensive services for our customers. So, what’s in store for the year 2024?

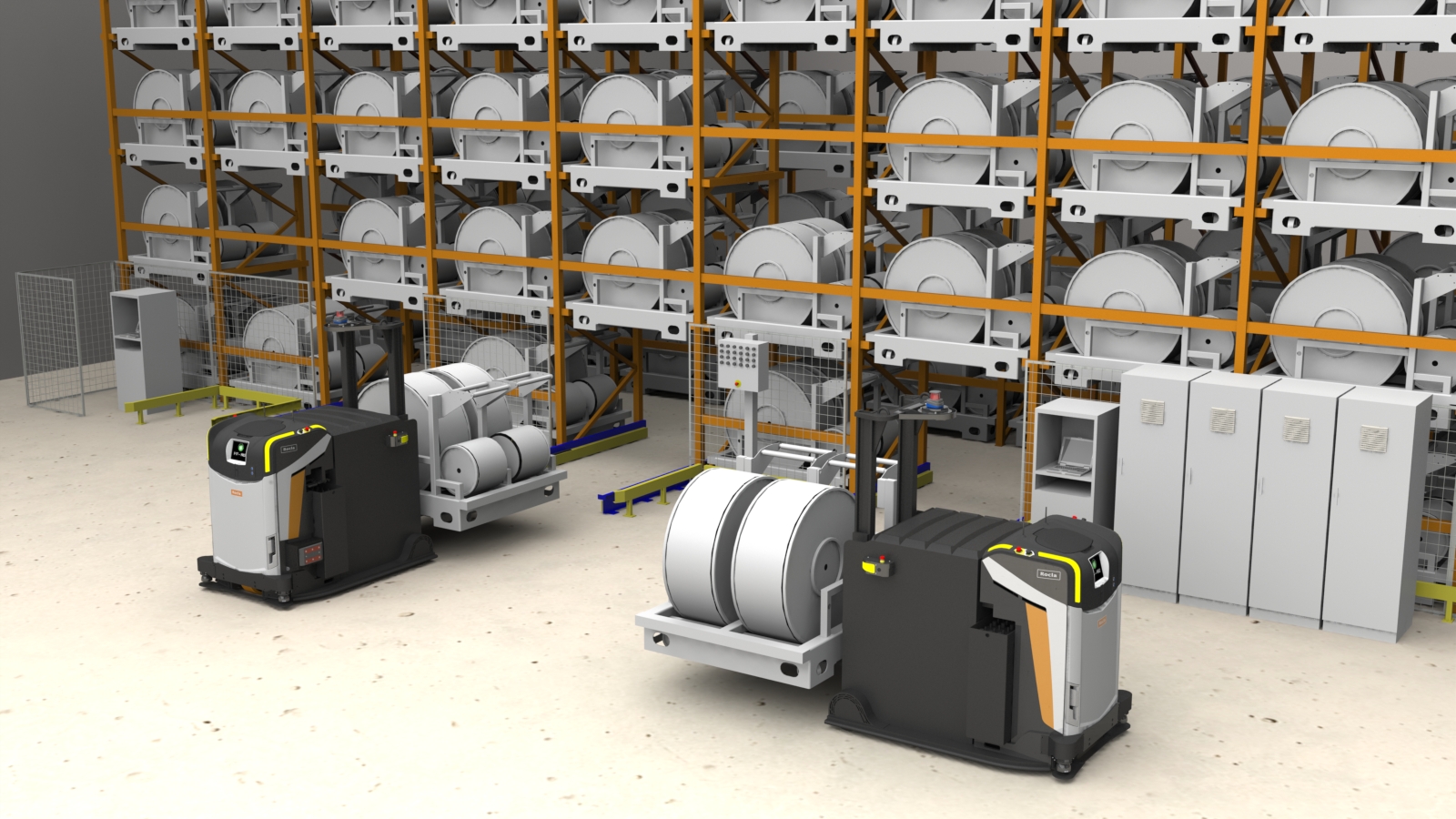

As a global solution provider, we offer various material handling solutions and services, from AGVs and manually operated forklifts to racking, software and intralogistics consultation with the continuously growing offering. The versatile offering goes well with our design principle, according to which automation can be introduced into an existing warehouse without modifications. There are options for all kinds of facilities with all sorts of processes.

“In recent years, we have ventured into the warehouse segment and increased our expertise in it. We are constantly developing our offering based on customer feedback. Now, our offering covers all lifting heights and different aisle widths. The latest addition to the Rocla AGV offering is ACT (Automated Compact Truck). ACT fits particularly well into aisles as narrow as 2,6–2,8 meters and lifts to 6 meters. Our principle is to ensure our customers a scalable investment in automation by having AGVs and manual lift trucks working together in the existing warehouse environment,” says Kari Johansson, Solutions Management Director.

No lone wolves in the warehouse

We believe the future of logistics is in optimal automation. The solution combines the best of AGVs and manual lift trucks to create a perfect mix for each customer’s process. In practice, this teamwork involves AGVs working with repetitive, tiresome and burdensome tasks, while humans can tackle the jobs requiring precision and creative decision-making. Fluent operations and seamless collaboration of AGVs, manual lift trucks and other people-driven operations make the logistics smooth and allow to adjust to variations in capacity demands.

“Our AGVs are not intended to be lone wolves, but they are genuinely made to work in cooperation with other vehicles and people. This approach means more than just hardware or software: automation is part of a comprehensive ecosystem of all the solutions we deliver to each customer to solve their intralogistics automation challenges. We are with the customer every step of the way to advise on what is worth automating and in what scope so that their business can enjoy the benefits of optimal material flow to a full extent,” says Matilda Suonpää, Product Manager of Warehouse Logistics Solutions.

One size doesn’t fit all – nor it should

Ensuring everything is in constant movement is essential for an efficient warehouse. Besides that, efficiency also means that all the variations in the operations are handled flexibly. For example, peak hours are handled with reasonable resources, and FleetController is there to help manage the task sharing between AGVs and manually operated lift trucks. This has a tangible effect on the warehouse personnel and their workload: the job becomes easier, smarter and more flexible.

“The innovative software isn’t a miracle maker on its own. The starting point of all planning must be in the customer’s processes. Hence, automation should not be forced. Instead, the solution should be tailored based on the actual processes and needs while supporting the existing operations,” says Suonpää.

“We build warehouse solutions that are not one-size-fits-all, but that are built according to customers’ needs – supporting, improving and enhancing existing processes without unnecessarily changing them. We think carefully about the processes that should be automated and where the best benefit comes from. Our team here does everything from the customer’s point of view: we understand the practice of your warehouse and what truly happens there in the everyday operations.”

Target: a perfect warehouse

Rocla AGV Solutions continues the journey towards a perfect warehouse with optimally automated functions. Material flow functionalities will be enhanced, and optimisation will become even more comprehensive.

“The development continues, and there is a clear roadmap, so more exciting things are coming soon! We make sure we follow the trends while listening carefully to our customer feedback, and we continue to improve our offering based on these. At the beginning of the year, the flow optimisation done on the AGVs is also carried over to the manual side: manually operated forklifts and AGVs will be able to share the same task queue. This means all functions can be optimised,” concludes Suonpää.