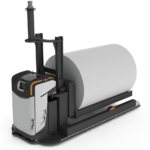

Reel Fork AWT

For efficient and reliable reel handling, Mitsubishi Logisnext Europe offers the Reel Fork AWT as a solution to the paper, packaging, and printing industries, in addition to those performing tissue and plastic reel handling.

Key Benefits of Reel Fork AWT

- Designed specifically for reel handling

- Ideal system for horizontal reel transport

- Variable reel diameters and widths

- Fixed or adjustable forks

- Loads of up to 8,000 kg

- Modular design

- Light-, medium-, or heavy-load solutions

- Special models for customer-specific loads

The Reel Fork AWT is optimal for conveyor pick-up/drop-off

AGVs can be used in conveyor pick-ups and drop-offs, also known as handshakes. Mitsubishi Logisnext Europe offers a range of solutions for this storage option.

The Reel Fork AWT is an ideal solution for efficient and reliable reel handling in the paper industry. In addition, this Mitsubishi Logisnext Europe solution suits the packaging, and printing industries, as well as those performing tissue and plastic reel handling. The Reel Fork AWT is equipped with fixed or adjustable forks for delivery of efficient material handling as your applications require.

The Reel Fork AWT is specifically designed for reel handling applications. It is an ideal system for horizontal reel transport in printing houses, paper mills, converting, and more. It is a versatile solution, with variable reel diameters and widths. The forks can be either fixed or adjustable, and can handle loads of up to 8,000 kg. The modular design enables the combination of tried and trusted components with automation. The Reel Fork AWT is available as a solution for light, medium and heavy loads, with special models for your specific loads also an option.

In the solution, the AGV is just the beginning of the story

Dimensional drawing

AWTsr Reel Fork ISO Ø1270-L1600

Download this document to learn more about the dimensional and space requirements of the Reel Fork AGV.

*Dimensions are indicative only. Details are subject to change.

Request a quote or more information

Would you like to start saving costs at your paper facility? Please send us a message and we will get back to you.

Lead Form

"*" indicates required fields