RICOH: Warehouse automation benefits. Constant material flow, lower cost and a safer factory

Ricoh Industrie France manufactures office automation equipment including multifunction printers, toners, recycled cartridges, thermal products and thermal transfer ribbons. Rocla automated guided vehicles (AGVs) take care of inner logistics at Ricoh’s thermal paper factory in Colmar, north-eastern France. Increased material flow and the need to rationalize operations led the company to seek a comprehensive solution for automating its production.

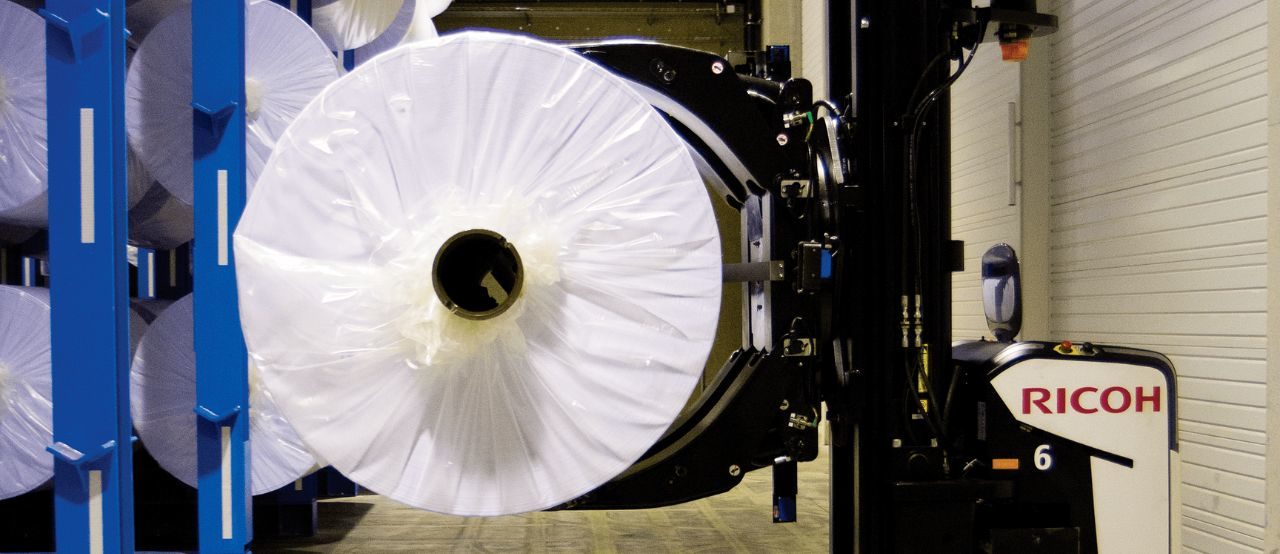

Ricoh’s thermal paper production process is automated with Rocla AGVs and warehouse management system (WMS). Clamp and fork AGVs take care of all material flow: AGVs transport raw material paper reels and pallets from arrival point to the production machines, from machines into the curing room, then into an intermediate stock and finally into loading area. Rocla AGVs also empty the trash containers.

“We had three goals for automation: first we wanted to secure a constant material flow with no stops in the line. Secondly, we wanted to reduce the manufacturing costs. Thirdly, but not least, we wanted to improve the safety in the factory. We have been able to find a good answer to all these three challenges with Rocla’s automation solution,” Stéphane Lamaze, deputy general manager of the thermal business group, explains.

The AGV system has also brought more space. Now it is possible to store even four paper rolls on top of each other, as earlier it was possible to store only two. The AGV system is also easy to install in an old factory. Ricoh is constantly working to minimize the impact of its activities on this environment. Rocla AGVs are also manufactured with consideration of environmental issues.

The system has been up and running since 2009. Over the years the automation system has been developed according to customer needs. Lamaze summarizes the good and efficient co-operation:

“The key is that both Ricoh and Rocla had a win-win spirit.”

Ricoh’s thermal paper production process is automated with Rocla AGVs