Automating tyre manufacturing processes

Blog post by Jarkko Uusitalo

Production is fluctuating because of an error in one part of the internal logistics process, and the tyre components aren’t moving through the manufacturing chain as they should; the disruption has many consequences and impacts the company’s finances and competitiveness—this is when automation comes to the rescue. Using AGVs in the tyre manufacturing process has multiple benefits.

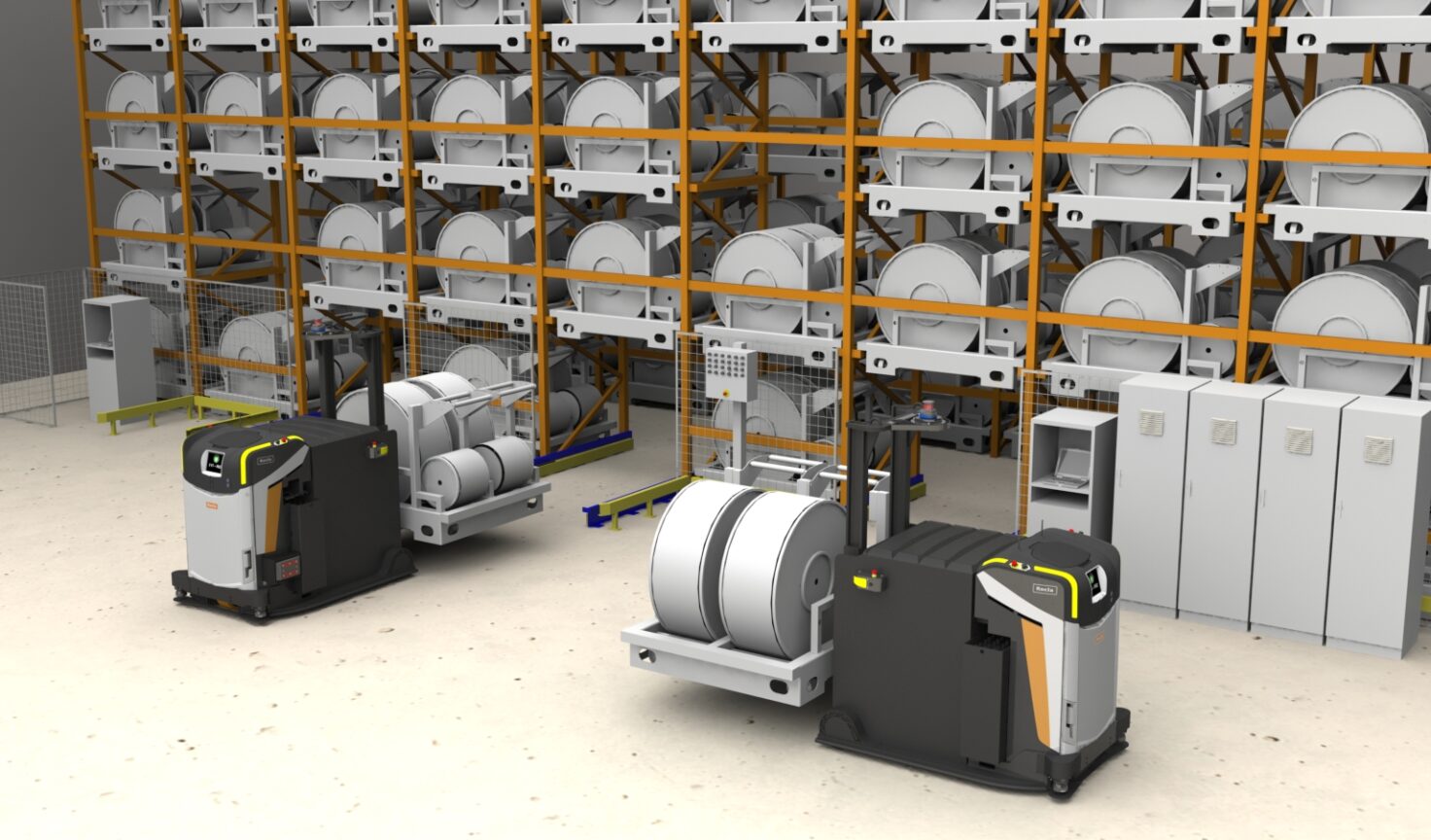

In a tyre factory, using AGVs can help improve material flow. Our experts usually begin by analysing your specific requirements and current processes, as each factory and project is unique. Understanding the factory layout and its existing systems is crucial.

AGVs can be fitted in different environments: both in new factories and existing premises. In greenfield cases, the factory layout design depends on factors such as the available space and other needs. One of the benefits of greenfield is that if noticed early on, the facility can be designed to consider the optimal conditions to run AGV logistics in the future. However, as creating a new factory isn’t the starting point for most companies, fitting AGVs into existing operations is also possible. This can involve some modifications to facilitate a seamless integration of the AGVs.

AGVs as part of tyre manufacturing

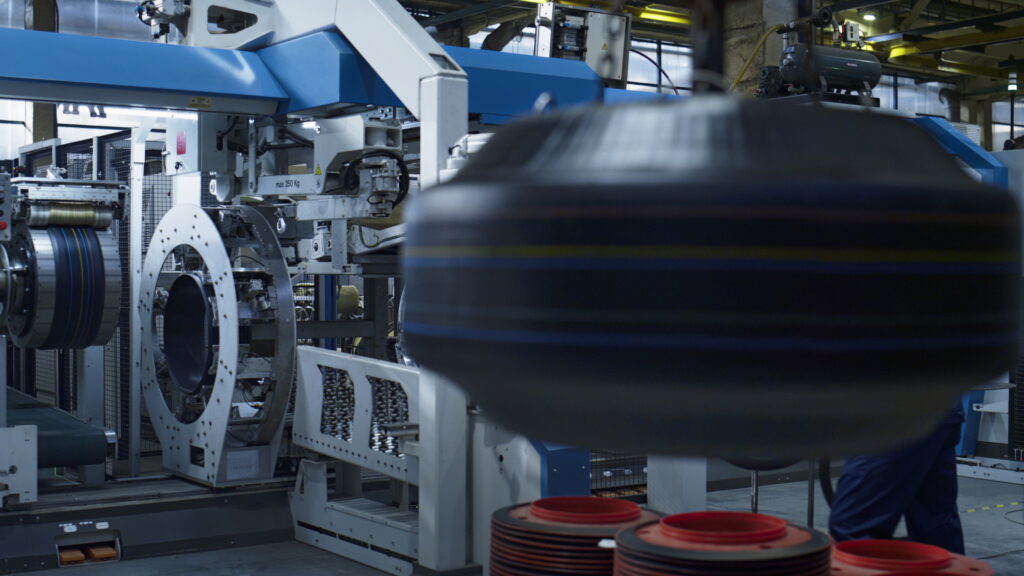

The tyre manufacturing process starts with the arrival of raw materials at the factory. Then, the material is picked up and moved to a space where it can be prepared for a specific component type. AGVs can already be used in this first transfer of raw material. However, it may not always be necessary or feasible for different reasons, such as the factory layout and the short distance to the material preparation. The type and quality of the material also matter.

After the raw materials have gone through the dosing and mixing processes, AGVs can be immensely helpful in moving the compound via the buffer stocks. They can also be used when transporting compounds to be manufactured into tyre components. The AGV routes and transport tasks are optimised, improving efficiency and quality while promoting lean practices. This efficiency and improved productivity can be seen in every step of the AGVs’ use.

The same principle applies to the following steps of the tyre manufacturing process. After curing and inspection, AGVs can transport the tyre components to be assembled into final products through a buffer stock. In each of these steps, transports can be done by AGVs, leading to cost reductions and improved productivity as AGVs are designed to operate non-stop. Additionally, with automated guided vehicles operating in the factory better quality control and reduced risks of accidents is ensured thanks to the increased predictability.

Tyre Industry Brochure

Maximise your logistic performance

How do the most efficient tyre companies in the world achieve their lean results? Through automation. Download this brochure to learn how.

Many possibilities of automation

The benefits of using automation in tyre factories aren’t only limited to the AGVs themselves but also to the FleetController, a platform connecting all components needed to run and manage efficient AGV operations. It is attached to a host software system such as the MES (Manufacturing Execution System) and keeps the fleet running by automatically optimising the orders and routes of material flow. This is the brain that facilitates improved factory traffic control and monitoring, which can be seen as enhanced in-time delivery and smaller AGV fleet size, thus optimal investments.

If automating the whole manufacturing process isn’t feasible, a mixed fleet solution can be a possibility. AGVs perform well in tiresome routine tasks, while driver-operated forklifts can be used for more demanding tasks and activities that don’t interfere with the daily production flow. For instance, the mixed fleet solution is useful in cases where some tasks can’t be replaced with automation or are otherwise dependent on human decision-making or manoeuvring.

Thanks to the comprehensive safety features and sensor technology of AGVs, they can operate synchronised with other types of transport as well as with people. The enhanced designs make communication between AGVs and humans even easier through, for instance, multiple safety scanners, sounds and lights following the ISO 3691-4 safety standard.

Every tyre factory and its processes differ from one another, and that’s why it’s important to consult with an experienced professional who can evaluate the possibility of achieving the desired level of automation in one’s factory. Factors influencing the assessment are related to the existing level of automation, the facility size, its condition, and the load type.

Main takeaways:

- Automation has multiple benefits for tyre factories, including improved material flow, increased safety, and optimal investments.

- Automation can be achieved in different environments. It is possible for both new and existing factories to accommodate AGVs.

- Automation can be used throughout the tyre manufacturing processes. FleetController ensures the production stream to be optimised.

- As every case is unique, contacting an expert is the best way to realise your ideas. The typical starting point is to determine whether the automation options align with customers’ wishes.

Send me a message or give me a call, and let’s chat more.